Complicated features can be machined on a industrial part - Parts can be indexed such as gears, splines, holes drilled around the circumference of the part. BUILD UP HARDWARE CO., LTD mainly engages in manufacturing and trading of all kinds of Custom CNC Machined Parts, such as Precision Aluminum Stainless Brass Parts, CNC Lathe Turning. We processing and manufacturing of all kinds of metal parts, such as screws, electrical, pneumatic tools, bicycles, clocks, instruments, medical equipment... and so on.

Sub Spindle & Back on CNC Lathe Machining

● Lathe Machining Diameter Size: 2mm ~ 36mm

● Machining Size: Within Ø 20mm x 400mm Length

● Machining Size: Ø 20mm ~ Ø 36mm x 120mm Length

Custom CNC Machined Parts

CNC Lathe Machining Products | Specification |

| Material: Stainless steel 304 grade Size: Ø16.0*16.0mm Surface: Mill Finish Through the hole size: Ø0.4mm Depth: 2.0mm |

| Material: Stainless steel 630 grade Solution treatment solution zing Size: Ø17.15*55.6mm Turning and Milling

|

| Material: SCM440 Back inner diameter Ø3.95±0.05 round groove *2 sides |

| Material: SCM439 Blue cross steel Size: Ø16.4*31.4mm Lathe and milling at one-time forming

|

| Material: C1100 Copper

|

| Material: S45C medium carbon steel

|

| Material: SUS 304 stainless steel |

| Material: SCM440 Red Cross steel |

| Material: SUS440C Stainless steel |

| Material: SCM415 Green Cross steel Size: Ø29 *97.7mm Process: Internal and external teeth, Lateral foramen, Wrench groove Anterior Ø10 H7 |

| Material: SCM415 Green Cross steel Size: Ø29 *97.7mm Process: Internal and external teeth, Lateral foramen, Wrench groove Anterior Ø10 H7 |

| Material: 6061-T6 aluminum alloy Size: Ø31 *5mm Thickness: One side 1.2mm |

| Material: 6061-T6 Aluminum Alloy Size: Ø29mm*52mm Process: Single side 1mm thin shell Inner and Outer Teeth |

| Material: ASTM A681 A.K.A S7 Tool Steel Size: Ø13mm x 180mm Roundness: 0.01 mm

|

| Material: 6061-T6 Aluminum alloy Size: Ø28.4mm*15.8mm Process: Double face to angle guide |

| Material: SCM440 Red Cross steel Size: Ø24.1 *34mm Process: Inner hole tolerance 0.02 mm Heat treatment: Tempering to HRC 28° processing |

More Machining Parts video

Available Steel for Machinery

● Free Cutting Steels

● Bearing Steels

● Carbon Steels for Machine Structural use

● Manganese Steels for Machine Structural use

● Structural Steels with Specified Hardenability Bands

● Nickel Chromium Molybdenum Steels for Machine Structural use

● Chromium Molybdenum Steels for Machine Structural use

● Manganese Chromium Steels for Machine Structural use

● Nickel Chromium Steels for Machine Structural use

● Aluminum Chromium Molybdenum Steels for Machine Structural use

● Alloy Steel Bolting Materials High Temperature Service

● Alloy Steel Bars for Special Application Bolting Materials

● Carbon Tool Steels

● Alloy Tool Steels

● High Speed Tool Steels

● Spring Steels

Steel Data for Reference

| JIS | AISI/SAE | DIN | GB |

| SS400 | A36 | - | Q235 |

| (SS41) | |||

| S15C | SAE 1015 | CK15 | 15 |

| -1.1141 | |||

| S20C | SAE 1021 | CK20 | 20 |

| -1.0402 | |||

| S45C | SAE 1045 | CK45,C45 | 45 |

| -1.0503 | |||

| S50C | SAE 1050 | CK50 | 50 |

| -1.1213 | |||

| S55C | SAE 1055 | CK55 | 55 |

| -1.1203 | |||

| SCM415 | - | 15CrMo5 | 15CrMo |

| (SCM21) | -1.7262 | ||

| SCM420 | - | 25CrMo4 | 20CrMo |

| (SCM22) | -1.7218 | ||

| SCM440 | SAE 4140 | 42CrMo4 | 42CrMo |

| (SCM4) | -1.7225 | ||

| SNCM220 | SAE 8620 | 21NiCrMo2 | 20CrNiMo |

| (SNCM21) | -1.6523 | ||

| SNCM420 | SAE 4320 | - | 20CrNi2Mo |

| (SNCM23) | |||

| SNCM439 | SAE 4340 | 40NiCrMo6 | 40CrNiMoA |

| (SNCM8) | |||

| - | - | 17CrNiMo6 | - |

| 18CrNiMo7-6 | |||

| SACM645 | SAE 7140 | 41CrAlMo7 | 38CrMoAl |

| (SACM1) | -1.855 | ||

| SUJ2 | 52100 | 100Cr6 | GCr15 |

| -1.3505 | |||

| SKD11 | D2 | X165CrMoV12 | Cr12MoV |

-1.2601 | |||

| SKD61 | H13 | X40CrMoV51 | 4Cr5MoSiV1 |

-1.2344 | |||

| SKH51 | M2 | S6-5-2 | W6Mo5Cr4V2 |

| (SKH9) | -1.3343 | ||

| SK 2 | W1-111/2 | - | - |

| (SK 120) | |||

| SK 3 | W1-10 | C105W1 | - |

| (SK 105) | -1.1545 | ||

| SUS303 | AISI 303 | X12CrNiS188 | 1Cr18Ni9MoZr |

| -1.4305 | |||

| SUS304 | AISI 304 | X5CrNi189 | OCr18Ni9 |

| -1.435 | |||

| SUS316 | AISI 316 | X5CrNiMo1810 | 0Cr17Ni1Mo2 |

| -1.4401 |

More Machining Parts for custom made photos

Sub Spindle & Back on CNC Lathe Machining Description

Multiple Tooling Systems 7-axis, Sliding Headstock, Back Milling Device

● All in One Operation: Turning, Milling, Drilling, Tapping, Cutting, Side Turning, Back Machining.

● Sliding head without a guide bush design provide faster setups, lesser remnants, and cost reduction.

● Multiple Tooling Systems: Suitable for versatile cutting applications.

● On the front side Tooling System, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools.

● On the back milling system, user can set 4 live tools.

● The maximum tool speed is 6000 rpm.

● User can install O.D. and I.D. tools on the back milling system.

● The Sub-Spindle Head moves on the precision roller type linear ways with extra-large span design for outstanding stability and positioning accuracy.

Sub Spindle & Back on CNC Lathe Machining Specification

| Model | CB-36M | |

| Control Unit | Controller | SYNTEC |

| Axes Travel | X1 / X2- Axis Travel | Ø36 ( Op:Ø32 )mm |

| X1 / X2- Axis Servo Motor | Ø36 ( Op:Ø32 )mm | |

| Y / Z1 / Z2- Axis Travel | TRB 36 (Op:Ø32) | |

| Y / Z1 / Z2- Axis Servo Motor | 185 / 290mm | |

| X / Y / Z- Axis Rapid Travel Speed | 1.3 kW / 0.85 kW | |

| Main Spindle | Max. Turning Dia. | 490 / 165 / 285mm |

| Max. Spindle Speed | 0.85 kW | |

| Center Height | 30m/min | |

| Standard Turning Dia. | 6000rpm | |

| Spindle Collet | 1032mm | |

| Spindle Servo Motor | 7.5 kW | |

| No. of O.D. Turning Tools | 6 (Optional 5) pcs | |

| No. of I.D. Turning Tools | 5 pcs | |

| O.D. Turning Tool Size | □12mm (Op:□16mm) | |

| I.D. Turning Tool Size | Ø25mm | |

| Spindle Live Tooling | No. of Radial Live Tools | 4 pcs |

| Radial Tool Size | ER-20 | |

| Radial Live Tooling Max. Speed | 6000rpm | |

| No. of Axial Live Tools | 3 pcs | |

| Axial Tool Size | ER-20 | |

| Axial Live Tooling Servo Motor | 0.75 kW | |

| Axial Live Tooling Max. Speed | 6000rpm | |

| Sub Spindle | Max. Bar Feeding Dia. | Ø27.5mm |

| Max. Sub Spindle Speed | 6000rpm | |

| Spindle Collet | TRB-32 | |

| Sub Spindle Servo Motor | 4.4 kW | |

| C-Axis Index Positioning | 0.001° | |

| No. of Turning Tools | 4 pcs | |

| I.D. Turning Tool Size | Ø25mm | |

| Sub Spindle Live Tooling | No. of Axial Live Tools | 4 pcs |

| Axial Live Tooling Size | ER-20 | |

| Axial Live Tooling Servo Motor | 0.75kW | |

| Axial Live Tooling Max. Speed | 6000rpm | |

| Power | Voltage stabilizer / Transformer | 220V / 20KVA |

| Hydraulic Motor | 1HP / 0.75 kW | |

| Spindle Upper Flush Pump | 1HP / 0.75 kW | |

| Tool Coolant Pump | 1HP / 0.75 kW | |

| Tank Capacity | Hydraulic Tank Capacity | 46L |

| Coolant Tank Capacity | 240L | |

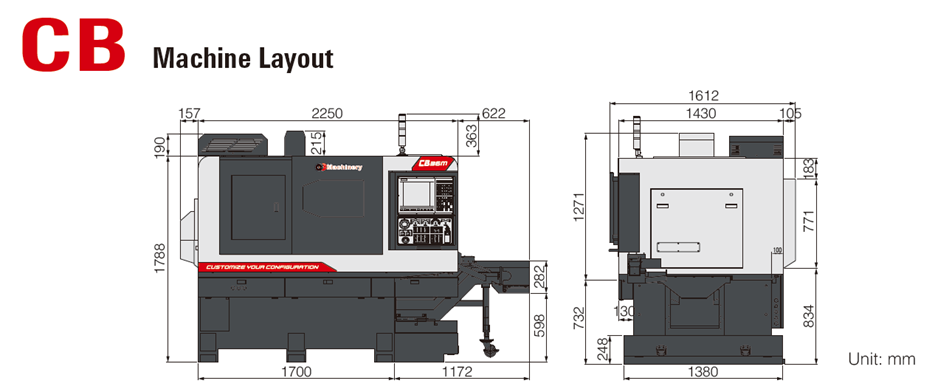

| Machine | Machine Size (LxWxH) (includes chip conveyor) | 3029x1612x2151mm |

| Machine N.W. (includes chip conveyor) | 4000kg | |

In addition to high quality products and the best service, we differentiate ourselves through the following advantages:

- Complete product line

- Top grade materials

- No MOQ

- Small quantity for OEM order is acceptable

- On-time delivery

- Competitive price

The launch of the CNC Turned Components for Industrial use is a significant milestone for Build Up Hardware Co., Ltd. as it expands its product line to meet the growing demand for precision components. With this new product line, the company is well-positioned to serve the needs of its customers across various industries.

To learn more about the CNC Turned Components and other products offered by Build Up Hardware Co., Ltd., please Contact Us or visit their website at https://stainlesssteeltube.en.taiwantrade.com/

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.